OXPEKK

Products

The world’s highest performance thermoplastic

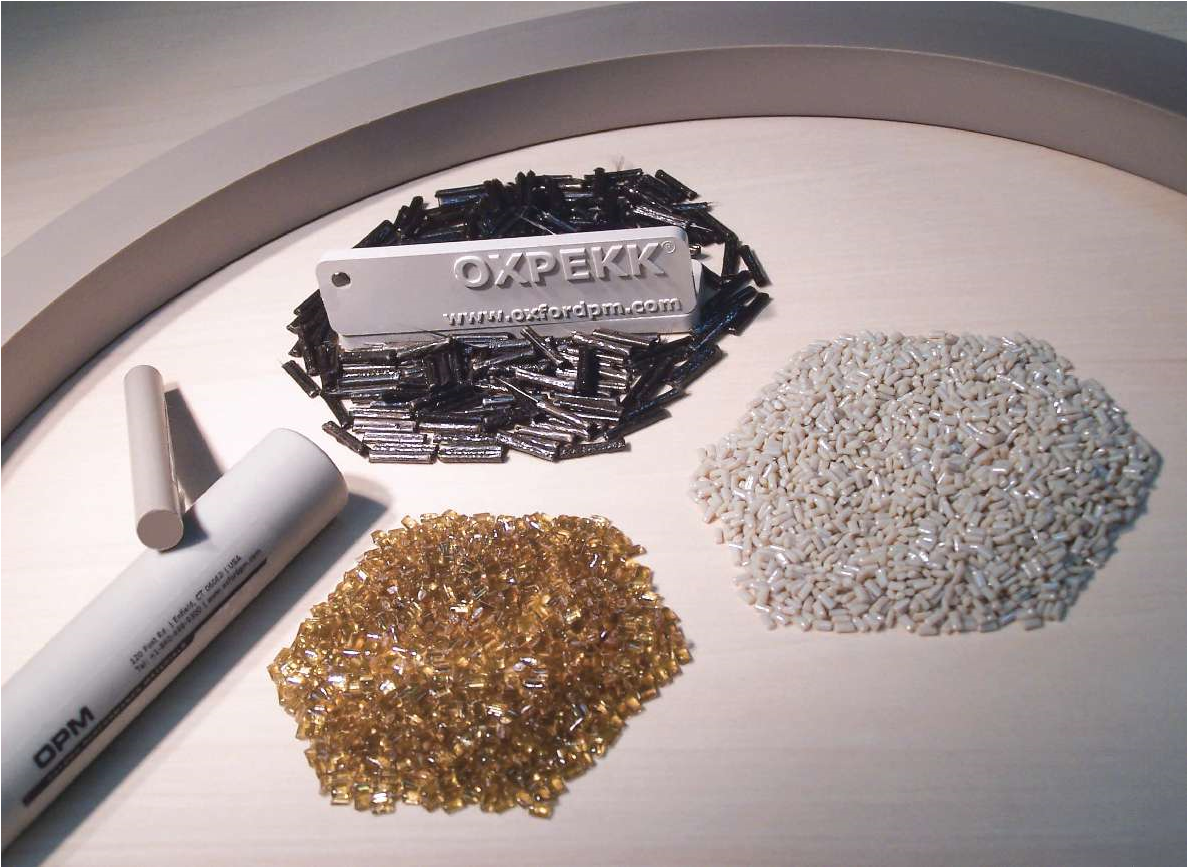

OPM offers OXPEKK® in standard product forms for implant and industrial applications

OXPEKK Rod

Custom and standard compounds

Available rod diameters - 8mm to 100mm

OXPEKK Pellet

Custom and standard compounds

Available fillers - carbon fiber, glass fiber, barium sulfate, titanium dioxide, colors, custom

OXPEKK Nanocoating

OXPEKK powder coatings can be applied at micron and millimeter scale thicknesses to provide an ultra high-performance, abrasion resistant coating on any suitable substrate.

Conformal PEKK barrier

Corrosion resistant

Industrial & Biomedical applications

OXPEKK Powder Coating

The world’s first aqueous PEKK coating technology. Applied by most standard methods, this coating can be deposited at nano- and micron-scale thickness

Patented, water-based PEKK solution castable as ultra-thin films that - when formed - have the full mechanical, thermal and biological properties of PEKK.

OXPEKK-SC film tenaciously bonds to most substrates and can be spray applied or dipped at thicknesses as low as 100nm.

Since OXPEKK®-SC is applied as a true solution; it enables the formation of ultra-thin, tightly adhered, contiguous layers of pure PEKK polymer.

advantages of OXPEKK

thermal characteristics

With a Tg of 163C and Tm of 360C, PEKK is highly suited to high temperature environments

chemical resistance

PEKK is one of the most chemically resistant thermoplastics on the planet

Mechanical strength

PEKK’s tensile strength (yield) of 136 MPa and compressive strength (207 MPa) make it the ideal replacement for metals in many applications

biological properties

PEKK has unique, bone-like mechanics and superior wear properties - all of the biological and biomechanical properties that make it the ideal replacement for bone

Co-polymer system

Unlike PEEK, we can alter the physical, chemical and thermal properties of PEKK to suit your application

Flame/radiation resistant

PEKK has a UL94 V-0 flammability rating and is near impervious to any amount of radiation

Additional Services

Machining

Through our network of qualified manufacturing partners, OPM can manage the machining and finishing of your OXPEKK product.

Custom Compounding

Looking for a material with specific properties? OPM will work with you to develop custom OXPEKK compounds that meet your application requirements.